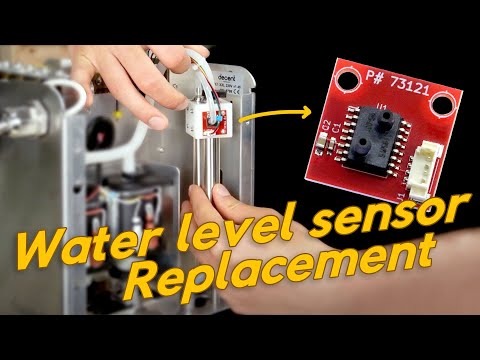

In this video, we'll walk you through how to replace the Water level sensor The Water level sensor includes

Sensor board

Sensor tube

Sensor cable

Tube Clip

We need to replace the Water Level Sensor when the water level reading is stuck at a point, although the actual water level in the tank changes.

Important: Do not open the board room or attempt to access the AC board without our guidance. The AC board carries high voltage. This video is part of a series that we produce, helping people self-repair their Decent Espresso Machine.

Only do this repair in consultation with Decent tech support

Doing otherwise might break your machine or void your warranty.

Water Level Sensor Replacement Instructions

Tools Needed

● T10 Torx screwdriver

● PH2 Phillips screwdriver

● PH1 Phillips screwdriver

● T20 Torx screwdriver

● Straight pointy tweezers

● Nippers

● 3 × Cable ties

Step 1: Power Disconnection

For XL or XXL Models:

1. Remove the back panel.

2. Turn off the machine's back switch.

3. Unplug the power cord.

For Pro and Plus Models:

1. Turn off the machine's back switch.

2. Unplug the power cord.

For Version 1.43 or Higher (Slide-Type Tablet Stand):

1. Unplug the USB cable.

2. Gently pull the tablet stand out.

For Version 1.3 to 1.42 (Screw-Type Tablet Stand):

1. Unscrew the three screws holding the tablet stand.

2. Remove the stand.

Step 2: Remove External Components

1. Remove the drip tray.

2. Remove the drip tray cover.

3. Lift the lever on the back of the machine.

4. Slide the water tank out and remove it.

5. Remove the portafilter.

6. Remove the group head handle.

Step 3: Remove the Main Cover

1. Use a T10 screwdriver to remove the 8 screws securing the main cover.

2. Gently stretch the sides of the cover outward.

3. Lift the cover off the machine.

Step 4: Remove the Chassis and Boardroom lid

1. Identify the screw type for the manifold (T10 Torx or PH2 Phillips).

2. Remove the 6 screws securing the chassis.

3. Remove the side screw of the boardroom lid (T10 or PH2).

4. Remove the lid.

Step 5: Remove the Back Panel

For Pro Models:

1. Remove the 4 T10 screws securing the back panel.

For XL or XXL Models:

1. Remove the 4 standoffs with an adjustable wrench or pliers.

○ Alternatively, use a T10 screwdriver to press and turn the standoffs.

2. Unscrew the intake pipe knob.

3. Lift the pipe slightly while holding the tube inside.

4. Remove the back panel.

Step 6: Remove the Old Water Level Sensor

1. Unplug the sensor cable from the DC board (point-tip tweezers).

2. Remove the top guide rod screw (T20 or PH2). Save the washer.

3. Remove 2 back screws on the bracket (T10 or PH2).

4. Remove the bracket.

5. Lift the uptake group off the guide rod.

6. Pull the sensor tube from the plastic and metal barbs.

7. Wiggle and pull the sensor cable from the board (straight tweezers).

8. Remove 2 PH1 screws from the sensor board.

9. Remove the board.

10. Cut cable ties on chassis and tube (nippers). Remove them.

Step 7: Install the New Water Level Sensor

1. Plug the new cable into the board (align the open side).

● Route the cable through the grommet.

2. Secure the cable to the chassis with a cable tie (not too tight).

3. Place the new sensor board on the bushing body.

4. Fasten 2 PH1 screws (align, then tighten fully).

5. Connect the tube to the intake pipe. Secure with a cable tie.

6. Connect the tube to the board barb with the clip:

● Squeeze the clip legs

● Slide the tube halfway through

● Attach to barb

● Slide clip to lock

7. Plug the sensor cable into the board (align the open side).

8. Tie the sensor cable to the F-type tube.

9. Insert the guide rod through the uptake group.

10. Install bracket, washer, and center screw.

11. Install 2 back screws.

Step 8: Reassemble the Machine

1. Reattach the boardroom lid (1 screw).

2. Reinstall the back panel:

● Insert the refill water inlet barb connector.

● Hold the panel while tightening the intake lever.

● Pro: Tighten 4 T10 screws.

● XL/XXL: Reinstall 4 standoffs (finger‑tight, then secure).

3. Reattach the side panel:

● Tighten the first 5 screws halfway.

● Then fully tighten all.

Chapters

00:05 Tools

00:11 Power Disconnection

00:32 Remove External Components

01:13 Remove the Main Cover

01:35 Remove the Chassis

02:17 Remove the Back Panel

03:13 Remove the Old Water Level Sensor

05:04 Install the New Water Level Sensor

08:19 Reassemble the Machine

#repair #dye #waterlevel #waterlevelsensor #howto #documentation #DIY